Cognitive and disruptive technologies like artificial intelligence, RPA, 3D printing technology, drones, and predictive analytics are steadily transforming supply chain processes. These technologies enhance collaboration between stakeholders, automate inventory and warehouse operations and generate real-time insights for better decisions. Read this blog post to explore how next-gen technologies are accelerating supply chain processes.

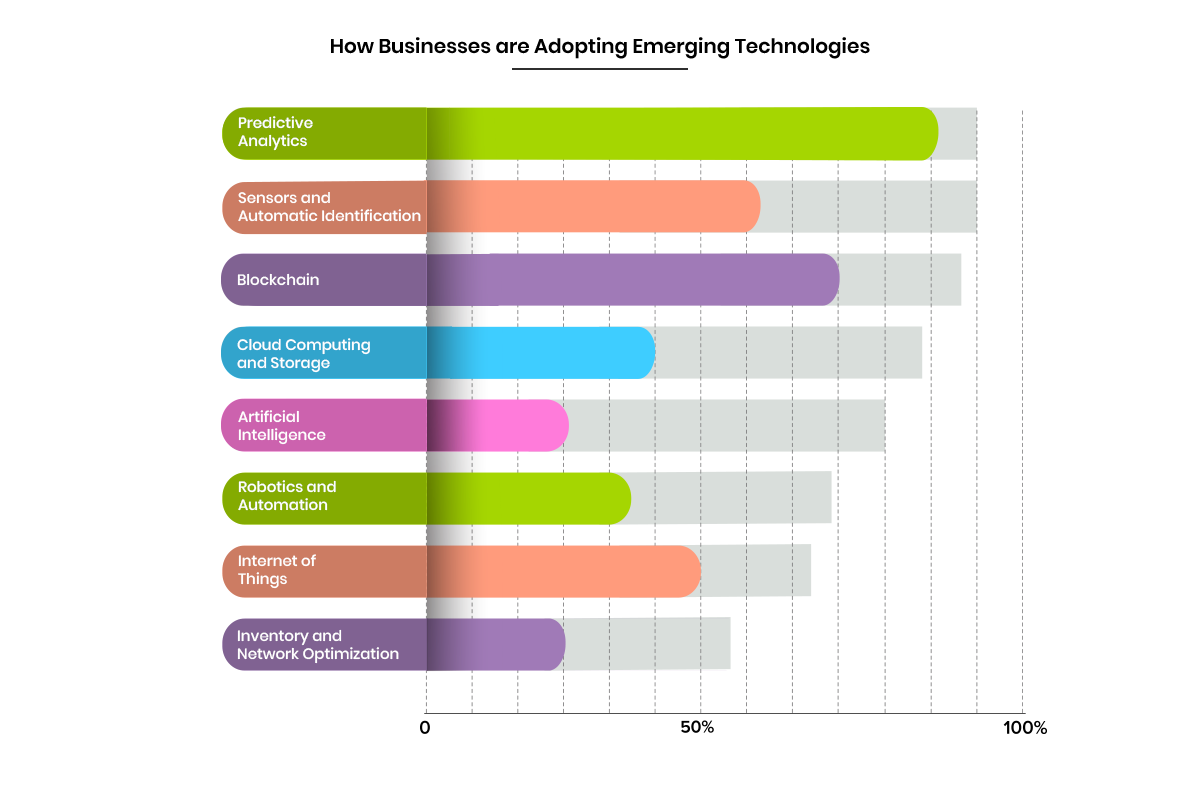

Traditionally, the focus of supply chain management was on streamlining logistical operations. Today’s supply chain management is about enabling advanced planning, operations planning, and demand forecasting. According to a Gartner Survey (2018), 96% of the supply chain leaders use predictive analytics, 85% use prescriptive analytics and 64% use artificial intelligence.

Technologies that are Transforming Supply Chain Processes:

The Role of the Internet of Things (IoT) in Supply Chain

IoT enabled smart devices are effective at tracking and authenticating products and shipments using GPS and other technologies. IoT increases the reliability of supply networks by optimizing asset utilization. Here are the key benefits of IoT in the supply chain:

Forecasting and Inventory: IoT devices enable the tracking of inventory including supplies in stock and evaluating future requirements. They provide accurate inventory levels so decision-makers can better plan sourcing and manufacturing activities. For instance, Amazon uses WiFi robots to scan QR codes on its products to track and triage orders

Asset Tracking: Tracking barcodes and numbers is now a standard method for managing goods throughout the supply chain. Manufacturers use IoT sensors to generate granular insights like since how long products were in cargo, what was the temperature at which the item was stored and how long it took for products to fly off the shelf. With such data, businesses gain better control over product quality, on-time delivery, and product forecasting.

Scheduled Maintenance: Businesses can use IoT sensors on their manufacturing floors to manage the plan and predictive maintenance of products. It also prevents downtime that can cost much.

Oodles ERP provides end-to-end customized supply chain development services that enable businesses to monitor and manage their inventory accurately.

Robotic Process Automation (RPA) in Supply Chain:

RPA in the supply chain enables businesses to reduce costs, minimize transaction times, increase productivity and improve compliance. It also enables businesses to experience a significant improvement in order quantity and order fulfillment accuracy.

Key Benefits of RPA in Supply Chain:

*RPA eliminates the possibilities of human error and duplication in the supply chain, resulting in higher quality outputs and streamlined processes.

*It reduces administrative overhead, lowers staffing costs and streamlines supply chain processes

*RPA can boost ROI by bridging the gap with suppliers

*RPA automates supply chain processes that were carried out manually to reduce anomalies and errors

Our ERP development team at Oodles has experience in building RPA solutions that enable companies to replicate human interaction with various business applications. We have the skills set to develop, design and implement RPA solutions.

Artificial Intelligence in Supply Chain:

Market research firm IDC reveals that by 2020, 50% of businesses will use artificial intelligence for planning and execution of supply chain processes. The main purpose of AI and supply chain integration is to create a fully automated and self-adjusted decision-making system. For a widespread supply chain uptake, combining pattern capabilities with advanced prescriptive capabilities is important.

Key Benefits of AI in Supply Chain:

*Integrating AI in the supply chain enables businesses to accurately predict demand spikes and adjust the volumes and routes of material flows.

*AI can streamline procurement tasks with automation and augmentation mechanisms

*An AI-powered supply chain enables stakeholders to track data, detect anomalies and generate predictions to improve supply chain operations.

Blockchain in Supply Chain Processes:

According to a report from the Capgemini research institute (October 2018), blockchain technology will become global by 2025. It will enter mainstream businesses and support supply chain processes.

In any supply chain transaction from manufacturer to buyer, there are multiple copies of purchase orders, transactions, logistics documents, inventory receipts, and transportation invoices. With so many copies of transactions, the risk of errors in the supply chain process increases. Blockchain is a distributed ledger technology that provides a transfer of ownership from one entity to another without involving intermediaries. Blockchain simplifies complicated and fragmented supply chain processes to achieve efficiency, transparency, and agility.

Key Benefits of Using Blockchain in Supply Chain:

*Blockchain technology enables businesses to track, exchange, honor agreements and execute payments

*It records every transaction on a block and across multiple copies of an immutable ledger that is distributed over many nodes, thereby making the transactions highly secure

*Blockchain provides integrity and reliability in supply chain processes.

*It reduces bureaucracy and paperwork that leads to process inefficiencies in logistics industries.

*Blockchain enhances traceability and addresses product counterfeiting issues with efficiency

Gain the benefits of integrating blockchain in the supply chain with Oodles ERP. Our development team has experience in integrating blockchain with different supply chain modules like warehouse, inventory, and accounting. We develop smart SCM solutions that provide tamperproof transactional records.

Concluding Thoughts

Supply chain processes are rapidly evolving and with that customer expectations too are rising. Customers now have a variety of options when it comes to deciding what to buy, where to buy, and at what price. To stay ahead of the competition and meet customers’ increasing demands, it is critical for businesses to ensure that their supply chain is faster, flexible, efficient and secure.

Demand and supply uncertainties can be overcome by integrating next-gen technologies. They can achieve better collaboration and a seamless flow of information. Businesses with an intelligent and agile supply chain can gain a competitive advantage that can build market leadership.

Talk to our ERP development team to explore the benefits we can provide with customized supply chain management solutions.