Robotic Process Automation: An Overview

Robotic Process Automation (RPA) is an application technology for deploying smart bots to automate routine business processes. It is useful for capturing and deciphering existing applications to process transactions, manipulate data, trigger responses and communicate with other digital systems.

Robotic Process Automation (RPA) in supply chain automates processes that are carried out manually, thereby reducing errors and anomalies. A McKinsey study (2017) predicts that supply chain automation could accelerate the productivity of the global economy between 0.8% and 1.4% of global GDP annually.

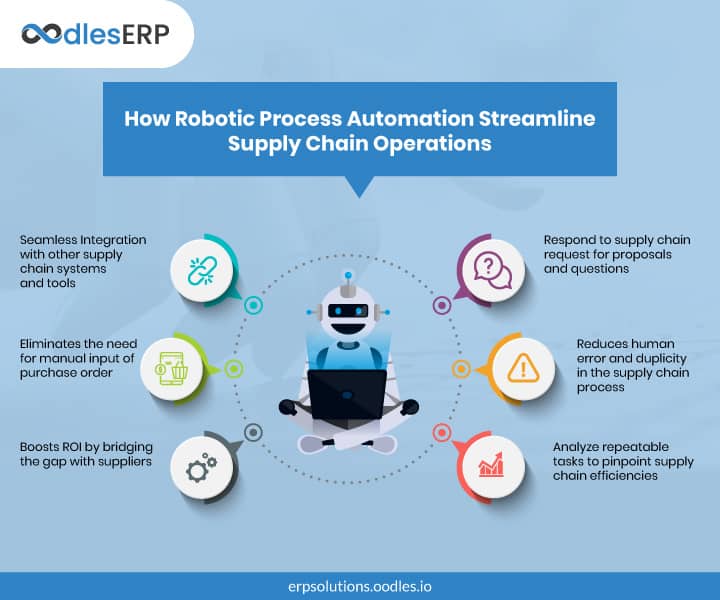

How Robotic Process Automation Streamline Supply Chain Operations

RPA in supply chain automates and accelerates tasks that were performed manually. It redefines the supply chain processes and reduces inefficiencies across the business.

Use Cases of Robotic Process Automation in Supply Chain Management

Email Automation

For optimized supply chain management, it is necessary for organizations to maintain effective communication between customers, suppliers, and manufacturers. An organization should ensure open communication during critical situations to build trust and credibility. Some of the critical situations are:

- Shipping delays

- Hindrances in order fulfillment

Robotic process management can optimize the supply chain by automating this communication. It will trigger an email to recipients when their order is processed, shipped or delayed.

Supply and Demand Planning

Planning is a necessary component of the supply chain, particularly for predicting future requirements of supply and demand. Before automation, it was a difficult task for supply chain stakeholders. They had to seek out and collate necessary data from vendors, market intelligence reports, and sales teams and represent data in a standardized format.

RPA bots can automate supply and demand planning processes in supply chain management.

RPA along with artificial intelligence and machine learning can enable organizations to predict demands. It can keep organizations in a state of readiness to cater to unexpected spikes in demand. Intelligent RPA bots have achieved success in automating various supply chain tasks to eliminate manual errors. They make operations smart, efficient and self-driven.

Vendor Selection and Procurement

Vendor selection is essential, but a time-consuming operation in supply chain management that involves manual efforts such as:

- Request for quotations

- Communication with vendors

- Performing preliminary analysis of vendor documents

- Evaluation of the vendor’s credit

- Finalizing vendor selection

After the implementation of RPA, organizations will be able to automate most vendor selection processes. Human intervention is required in the initial stages to specify the projects, generate vendor lists and engage in face to face negotiations.

Post automation, RPA bots can access credit value and finalize vendor selection in accordance with predefined criteria.

Order Processing and Payments

In a typical supply chain, order placement and processing occur in three phases:

- Selection of product

- Processing of payment

- Confirmation of order placement

Most enterprises rely on paper documents to process these transactions. But, it leads to inaccuracy and excessive time consumption. RPA in a supply chain enables organizations to automate these back-office tasks and minimize manual efforts.

Shipment Status Communication

Most enterprises regularly receive inquiries from customers about the status of their order shipment. Before automation, shipment status communication was entirely a manual process. Customer service agents had to open the email of a customer and then open a shipment system to find the shipment record in ERP software. They would then gather the necessary information and sent a shipment status update to customers.

RPA in supply chain automates the complete process from opening an email, addressing customer needs, logging into the ERP system and communicating exact status to customers.

Also Read: Cloud Computing to Revolutionize Supply Chain Management

Challenges of Using Robotic Process Automation in Supply Chain

Organizations face several challenges in implementing effective robotic process automation in their supply chains. Following are some of the challenges:

Standardization of Process

Process standardization is a critical challenge for organizations in the journey of RPA. Complexity in the process increases the cost of implementing RPA, operating costs and business disruption.

Employee engagement

For achieving success in scaling RPA, an organization needs to engage its stakeholders and gain their buy-in to change processes. The organization needs to take various steps so that all stakeholders accept RPA with minimal resistance.

Infrastructure Issues

One of the biggest challenges in implementing RPA is infrastructure. An organization should have an infrastructure to implement and deploy RPA. The implementation will become complicated if the organization does not have an interconnected system to update cloud infrastructure in real-time.

Gain the Benefits of Robotic Process Automation in Supply Chain with Oodles

We, at Oodles ERP, provide end-to-end customized development services to organizations that require enhanced supply chain planning and execution. Our SCM solution team develops custom solutions with open source platforms like Odoo and Ofbiz.

We develop Supply Chain Management (SCM) solutions like Inventory management systems, Electronic Data Interchange (EDI) and Order Management Systems.

We have experience in building RPA solutions that enable organizations to replicate human interaction with various business applications. From RPA design and development to RPA implementation, we offer a full range of services.

In addition, we provide order management solution development services. Our supply chain software development includes integrate and automate order processing requirements with shopping cart systems and point of sale purchase. We develop asset tracking solutions to provide seamless tracking experience across mobile devices and desktop. The asset tracking solutions enable end-users to gain real-time visibility of goods with inputs from Radio Frequency Identification (RFID) and barcode scanners.

Our experts enable organizations to store and automatically populate contract-based rates between enterprises while generating an auditable record. We enable organizations to eliminate the need for manual communication and streamline payment processes.

Concluding Thoughts

Robotic process automation in supply chain management enables organizations to experience a significant improvement in order quantity and order fulfillment accuracy. It also reduces shipment delays to enhance productivity and customer satisfaction levels. According to MarketsandMarkets, the RPA market between 2017 and 2022 could see a 30.14% compound annual growth rate. Moreover, RPA is the beginning of a digital transformation for organizations. It can be systematically broadened to include advanced technologies such as AI Artificial Intelligence(AI) and Machine Learning (ML).

To Read More: ERP in Supply Chain Automation